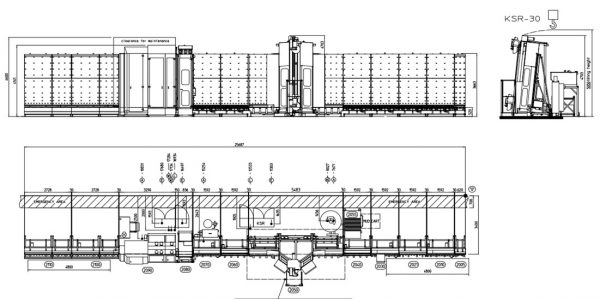

LISEC KSR-30 + KSV + VHW-30/6

LISEC KSR-30 + KSV + VHW-30/6

EnquireMake : LISEC

Model : KSR-30 + KSV + VHW-30/6

Description : Arrising and Wash Line

Complete automatic glass edge arrising (seaming) line, 3000 mm, R-L 60198 LISEC KSR-30 + KSV + VHW-30/6, year: 2014

Condition: very good and clean, good working order.

Maximum glass size: 3000 x 5000 mm,

Minimum glass size: 180 x 350 mm.

Line consists of:

RTVB-06/30AE

RTVB-15/30MZK (with automatic glass height measuring – increases working speed)

RTVB-15/30AE

RTVB-15/30WEK

RTVN-15/30WEK

KSR-30 (with shapes, flat edge grinding and corner dubbing options)

WRA-1000 (water cleaning system with water tank)

RTVN-15/30WEK

RTVB-15/30WEK

KSV-30 (additional bottom grinding belts at washer inlet (fast version)

VHW-30/6

RTVB-27/30ST

RTVB-27/30ST

– Installation, commissioning and delivery.

– Viewing by appointment only

Age : 2014

Price : Price on Application